If you are having problems with your concrete, call experts right away. They will show you the most effective methods of repair and restoration for your property. Listed below are some of the most common types of concrete repair. They include concrete leveling, concrete patching, and concrete leveling. Once you understand the various types of repair, you’ll be better equipped to select the right one for your property.

Cracks and uneven concrete are telltale signs of structural damage. A professional company can assess your situation to determine whether or not it’s time to go ahead with repairs or replace the entire structure. If the cracks and unevenness are not too extensive, you can often choose to level the concrete rather than replace it entirely. To save money, consider hiring a professional concrete repair company to assess the damage and determine whether it’s worth replacing. However, it’s important to remember that the cost of leveling concrete is usually much cheaper than the cost of replacing it entirely.

Cracks and uneven concrete are telltale signs of structural damage. A professional company can assess your situation to determine whether or not it’s time to go ahead with repairs or replace the entire structure. If the cracks and unevenness are not too extensive, you can often choose to level the concrete rather than replace it entirely. To save money, consider hiring a professional concrete repair company to assess the damage and determine whether it’s worth replacing. However, it’s important to remember that the cost of leveling concrete is usually much cheaper than the cost of replacing it entirely.

Before you begin, make sure the area to be repaired is moist. You can cover it with a plastic or burlap sheet to minimize any moisture and prevent drying. The longer the area is wet, the more likely it will develop a bond between the new and old concrete. In addition, the longer the area is moist, the less likely it is to shrink or loosen. Finally, you can use heat to harden the area.

Major defects need a different approach to repair than minor ones. A repair should begin as soon as possible before the original concrete shrinkage begins to take effect. The repair should be as close as possible to the original concrete, and should not have any cracks or delaminations. If the area is clean and moist, the repair should work as well. A properly done repair should make the existing concrete a seamless part of the finished product.

Cracks in concrete are not only unsightly, but they can also be harmful to the structural integrity of your home. They can cause foundation issues if left untreated. You should contact a concrete repair company to inspect your concrete surface for cracks. You should know that cracks can become worse as time goes on, so crack repair is vital. So, how do you go about it? Here are some tips:

Before you begin the repairs, you should prepare the area well. If there are any crumbling areas, you can remove them with a heavy-duty trowel. For larger areas, you can use a sled and cold chisel. Once you have removed loose edges and cracked concrete, you can apply the cement repair solution. After that, you must level the surface. This will allow the repair to bond to the concrete. Then, you’re ready to proceed with the repair.

Before you begin any concrete repair, you should carefully assess the structure to be repaired. Consider the factors that cause concrete failure. The repair methods must be effective. You’ll need expert help in determining the best method of repair for your specific situation. Remember that concrete repair techniques vary, so it’s best to consult with an expert first. In addition to ensuring the structural integrity of your structure, you should always consider the cost and the overall service life of your repair project.

The bond strength of a concrete repair material is one of the most important factors that determine the durability of the repairs. Regardless of the type of repair, it must be able to adhere to the original concrete surface. The bond strength of the repair material depends on the roughness of the concrete substrate. For example, epoxy-based materials are best used on surfaces that are dry enough to allow the cement to bond with the repair material. The substrate should also be dry enough to allow the repair material to adhere and set properly.

In addition to chemical and mechanical factors, physical damage to concrete can also be caused by heat, moisture, wind, and abrasion. Physical factors can cause concrete damage in two main categories: surface wear and damage due to abrasion, and cracking due to normal structural loading. The deterioration of concrete requires a proper diagnosis. Concrete repair services can help you find and address the root cause of the damage so that you can prevent it from worsening.

Category: Concrete

Advantages of Concrete Patios

You may be surprised to know that concrete is the cheapest building material available. While natural stone and other materials may be more expensive, concrete is a versatile and durable option for any patio. The advantages of Concrete Patios are plentiful, and you will love how versatile they are. Here are a few reasons you should choose this material for your patio. Here are a few tips to help you get started. If you’re planning to add a patio to your house, make sure to read these tips.

First, concrete is a natural material that is extremely hard, making it a great choice for a patio. This type of concrete is durable and can be easily stained with warm colors to add to a rustic look. In addition, it’s easy to find matching pathways to complement concrete patios. In case you’re considering a tropical patio design, you can use concrete with elements from the beach. This will add to the overall feel of the patio.

After you’ve installed the concrete, you can enhance the appearance of your patio by purchasing accessories and furnishings for it. For example, you can add a blender, an instant pot, a juicer, a food processor, a stand mixer, or a coffee maker. Then, you can enjoy the beautiful views of your property while you cook up some tasty treats! If you’re not a huge cook, then consider investing in a small kitchen appliance, such as a blender.

When choosing a concrete patio for your home, you should consider its weather and location. This material will withstand any type of weather and will need little maintenance. While you should seal the surface, you should clean it daily to prevent staining and maintain its good look. You can use a pressure washer to remove the debris, or you can also use a scrub brush and apply TSP or oxalic acid to the surface.

In addition to concrete, it is an incredibly durable material. Its durability and attractiveness make it an excellent choice for any landscape. When it comes to outdoor areas, concrete is an excellent choice for both warm- and cold-weather conditions. For example, if you live in a warm climate, concrete is a great choice. Its durability and aesthetic appeal will last for years, and it will look great in any backyard. When it comes to patios, a concrete patio can be used to create many different types of furniture.

Another advantage of concrete is that it can be customized. Besides being durable, concrete patios can be customized with a variety of designs and patterns. For example, you can get a stamped concrete patio or an exposed aggregate one. You can even add a decorative stone or a gazebo to it. This material is ideal for a warm-climated home, so it’s easy to customize with other materials. If you don’t want to use concrete, you can opt for other materials.

Unlike natural stone, concrete is an excellent choice for landscapes that have warm climates. However, concrete patios can be damaged due to extreme freeze-thaw. Some landscaping companies in northern states recommend using a sealant to protect their concrete patios. Alternatively, you can choose a chemical-free alternative. In addition to applying sealant, you can also use fertilizers to remove spilled drinks. But keep in mind that while concrete is a good choice for landscapes, you should also consider other factors.

Decorative concrete can mimic the look of more expensive materials. It is possible to stamp, texture, and stamp concrete to make it look more like real stone. A patio can also be used as a focal point and a garden. You can incorporate some flowers and shrubs as well to enhance the appearance of the patio. You should also choose a concrete sealer that suits the surface of the patio. If you’re unsure of what type of sealer to choose, follow the manufacturer’s instructions.

In addition to the above benefits, concrete is also an affordable material that is durable and can be customized to your preferences. You can create a patio in your own backyard with a custom design, or you can purchase a premade concrete patio from a local home improvement store. It is also a great choice for do-it-yourself projects. This material allows you to use different colors and textures for your patio, which will make your property more appealing to buyers.

You can also visit our other websites and post your article.

Conduit Hardware,78 Britnell CRT, Aqua Tremblant, Win Cheap Guest House, Quick Response Plumbing, Tighgeal, Kyles Peace, Sylars, Beans Ferry Pottery, Central Counselling, Project Homesc, Tree Aurora,Kitchens Bathrooms Floors, New Horizons Tree Service, Howell Shandyman Remodeling, Blue Star Remodeling Il, 48 hour Camaro, Colorado Health Insurance, Yes To Save Homes, Boise Chiropractor, Paperless Office Solution, United 4 Safety, Ab Sessions Plumbing Building Services, COCSBDC 2, Loving Care At Home, Team You, Business Savvy, Iric Insulation, Nexusea, Housing Counseling Association, Auto Front Office, Becker Village Mall, SR Internet LLC, Susan Sell Severett , SEO Columbus Ohio, Lake Of The Ozarks Propane Home, Indy Folkfest, The Green Wood Kitchen, Akbar Concrete Works, Naperville Inspector.

How to Repair Stamped Concrete

Concrete Contractors have several ways to repair cracked and broken stamped concrete. Surface tears are more common during certain weather and temperature conditions. A low-solids acrylic sealer can be applied to ease the pain and bring back the color. A walk-behind sander or a buffing machine can be used to remove the rough edges. Although this method may be expensive and time-consuming, the results will last a lifetime. Here are a few ways to fix your cracked or damaged concrete:

First, you must determine the type of distress on your concrete. If the distress is severe and requires patching, you may opt for a textured surface. This type of repair is also more affordable than other forms of repairing cracked or damaged concrete. The best way to do this is by using a paint spray. Simply use a small amount of paint on a rag to cover the discoloration and then apply the color.

After choosing the color of your new concrete, you need to match it with the old one. There are many coloring agents on the market. The best ones to use are water-based metallic oxide pigments. Once you’ve chosen the color and texture of your repair concrete, you must seal it to protect the surface from oil and improve adhesion. You should also perform this task in temperatures that range from 50 degrees to 90 degrees, as it could cause cracks or deterioration of the concrete.

If you’ve recently installed a patio or a pool, you might have noticed tiny tears in the concrete. These are often mistaken for cracks and can be difficult to detect. However, these tears are actually caused by the stamping tools used during the process. Workers push down the stamping tools, causing downward pressure on the concrete and side-to-side or outward pressure that pulls the concrete apart. Fortunately, the repair process is simple and inexpensive, but if you’re not careful, it could ruin your concrete.

If you’re not sure how to fix your damaged stamped concrete, you can contact a professional for help. They will know the exact type of repairs you need and will be able to give you an estimate of how much they’ll cost you. If you’re in a hurry, you can wait for a few days before completing the repair. When the repair is complete, you’ll need to use the same stencil again to cover the entire area.

Using a water-based concrete sealer is an excellent way to restore your cracked concrete. A sealer will protect the concrete from oils and prevent it from staining and peeling. To avoid the need for costly repairs, be sure to use a high-quality product to maintain your concrete. It’s also important to remember that sealing is essential for protecting your investment. If your stamped-concrete repair needs to be waterproofed, you can apply a waterproof barrier on the damaged area.

It is very important to match the color of the new and repaired concrete with the original color of the original concrete. A variety of coloring agents are available in the market. Try using water-based metallic oxide pigments for this purpose. Ensure the sealing of the concrete before you start any repair work. You must be sure to keep the temperature above freezing during the repairs so that the color won’t change. Once the job is done, it should be ready to use in no time.

It is vital to match the color of the new and repaired concrete with the existing one. The repair needs to be done carefully and the patch should match the original concrete color. The patching material should be of the same color as the original concrete. The color should match the surrounding area of the concrete. The color should be the same as the original. Afterward, you can seal the patched concrete. This way, you can get a more uniform look.

When it comes to stamped concrete, you must ensure that the repaired area retains the original pattern. In addition, it is important to make sure the repair material blends with the existing color of the concrete. To achieve this, you must remove any loose particles and clean the area thoroughly with soapy water. Then, you should use a sealant to protect the repair. This will prevent any further damage and preserve the integrity of the installation.

What is a Boom Pump?

Have you ever come across a concrete boom pump before? Unless you work in the construction trade, you may be forgiven for not really knowing what a boom pump actually does. However, for commercial and residential construction projects alike, it’s one of the most useful concrete pumping and layering tools out there.

What Exactly is a Concrete Boom Pump?

A concrete boom pump truck is an item that will help to deliver and pour concrete to projects which might have work being undertaken high off of the ground. For example, you may be working on a high-rise building or a block of flats, and it might otherwise be tricky for you to get concrete or cement up to such a height.

A boom pump offers a hydraulic arm, which stretches up from the vehicle’s base level to pump concrete directly to the project area. A boom pump can arrive via truck, so that you have a mobile unit at your disposal, or you can also invest in static systems, too. Of course, there are no right or wrong answers as to which system works best here – it’s all a case of considering your individual needs!

You’ll likely want to invest in a concrete boom pump if you are struggling to get those trickier bits of your construction or building project layered in concrete from a standing level. In many cases, this type of pump will take away plenty of time and effort and will make sure that there is less labour involved with concrete layering.

How Else Might a Boom Pump Device be Helpful?

As mentioned, the boom pump system is great if you have high-level concrete pouring needs. It’s also a fantastic asset if there are obstacles or obstructions in your way, and normal concrete pumping or pouring systems are unable to support you.

You might also find that this type of concrete pump is ideal for pouring mix from above down onto a project. Ultimately, you’ll find that a boom pump is going to give you easier access to some of the trickier points and fixtures which traditional concrete solutions just can’t handle.

The best news is that a boom pumping system is very flexible, meaning that while you can generally expect a stretch of around 72m at basic length, you can also invest in extensions or ask for additional help from concrete suppliers.

Is a Boom Pump Right for my Project?

If you are finding laying foundations difficult due to tricky to reach spaces, then a concrete boom pump vehicle could make all the difference. Why not take a look at the pump options available and take a chance on a more flexible system and operation for your building and construction needs?

There’s no need for you to be doing more work and taking on more hassle than you need to. A fantastic boom pumping system could save you time, money, and energy. Take a look at what’s available and compare! If you would like to find out more about how we can help you, get in touch today on 07812 182778 or head over to our contact page for more details.

The post What is a Boom Pump? first appeared on Base Concrete.

Phytodepuration with Degre.47

Depurating Landscape: an introduction to plants as a water treatment alternative

This article is a collaboration between Degré47 and Critical Concrete, aiming to be an introduction to phyto purification’s general concepts for self-constructors. It also aims to shed light on these systems as low-cost, low-tech and self-constructible wastewater treatment solutions.

The wastewater issue

It isn’t new to argue that the disorganized and centralized population growth in urban areas has brought challenges to the natural environment. In addition to CO₂ emissions, waste production and impermeabilization of soil, wastewater is one of the fundamental issues local governments need to address. At the very least, the wastewater from human activities of any sort needs to be treated to be assimilated by nature.

There are many water treatment solutions, from the collective to the individual scale. One of the most common sanitation solutions in urban centres is a collective one: wastewater treatment plants. These centres manage the wastewater through physical, chemical and biological processes in a complex and highly specialized infrastructure. [1]

After the physical filtration through decantation, flotation, filters and/or membranes, traditional treatments commonly make use of chemical products, notably coagulants (ferric chloride, aluminium sulphate, etc.), flocculants, and sometimes disinfectants such as chlorine or ozone. These processes, however, are arguably costly and energy-intensive, not to mention polluting. They also necessarily generate by-products such as coarse waste, sand and sludge that must be cleaned, decanted, stabilised and treated. [2]

In addition, in the ever-growing urban centres, many areas aren’t able to access the public sewage system, bringing up the importance to think of alternatives for wastewater treatment, especially low-cost and low-maintenance ones, as the mismanagement of effluents can pose a serious issue to natural hydric resources. [3]

Individual or small-scale collective sanitation solutions might be a good way to tackle the situation. A solution that stands out is the phyto-purification system with its low energy and low maintenance (as there’s no need for emptying and transporting). It is already the main sanitation system in France for cities of less than 1,000 inhabitants. [4]

This system, which is based on the use of plants (phyto) to filter the wastewater has been proving to be a low-cost yet highly efficient way to treat domestic wastewater. Because it is energetically and logistically autonomous, phyto-purification can be considered an ecological sanitation solution.

Purification with plants

Phyto-purification consists of wastewater purification systems that make use of aquatic plants, reproducing water depuration processes typical of humid areas. There are two main methods of phyto purification: lagooning, which consists of ponds with microphytes, similar to natural wetlands, and the filters planted that make use of macrophytes and consist of ponds filled with aggregates in which the water circulates for treatment. [5]

In these systems, the plants are responsible for bringing oxygen through their roots whereas the aggregates act not only as a physical filter — as bigger particles can’t penetrate it — but also as a chemical filter as they absorb phosphorus and ammoniacal nitrogen. In these basins, an important biological process also occurs: the microfauna present in the system degrades organic matter, turning it into nutrients to be absorbed by the plants. [6]

The interesting aspect is that, although the name might indicate, the wastewater is not filtered by the plants. In reality, the plants are the key element to create the environment for bacterial activity, especially in the region around the plants’ roots. The plants greatly benefit from the system as it absorbs nutrients that are liberated in the process of depuration. It’s a symbiotic relationship.

The different methods

There are two groups of phyto purification systems that can be used according to different needs and types of wastewater: lagooning and filters planted. [7]

Lagooning

This system makes use of microphytes (small aquatic plants), microorganisms and (sometimes) substrate to control water pollution. Its main characteristic is the resemblance with natural wetland areas in which the majority of elements are saturated, i.e submerged in water. [8]

In this model, the main purification process occurs on the aquatic surface where the plants and the bacteria present in their roots are located. In this solution, the effluent is continuously supplied and homogeneously distributed on the surface, flowing horizontally and superficially at low scooping velocity. The water is then collected by a drainage pipe located in the basin’s bottom. [9]

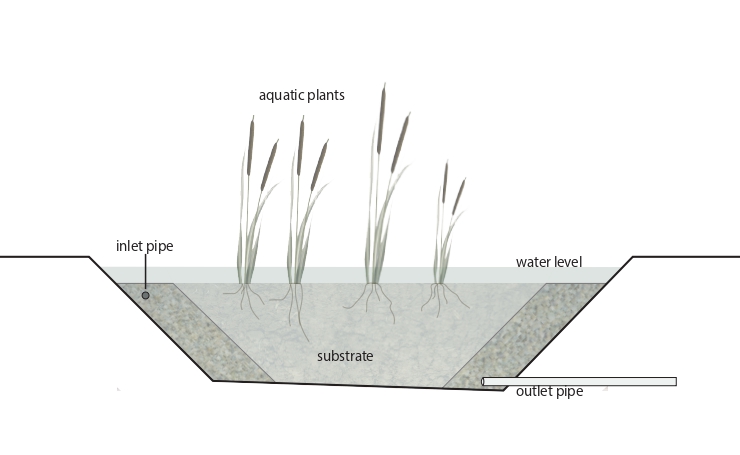

It is important to stress that in this solution, the substrate is not a requirement, and when not applied, fluctuant aquatic species should be used (see image 1). [10]

fig. 1: Different types of plants

Because there’s no emphasis on physical filtration with a substrate, this solution requires a previous treatment focused on the removal of organic matter and suspended solids as it mainly targets the removal of nutrients, especially phosphorus by the plants and bacteria. [11] The use of a substrate, however, can be beneficial if residual suspended solids end up in the basin.

This is a cheap and very low maintenance option, however, it generally requires a larger area than other methods.

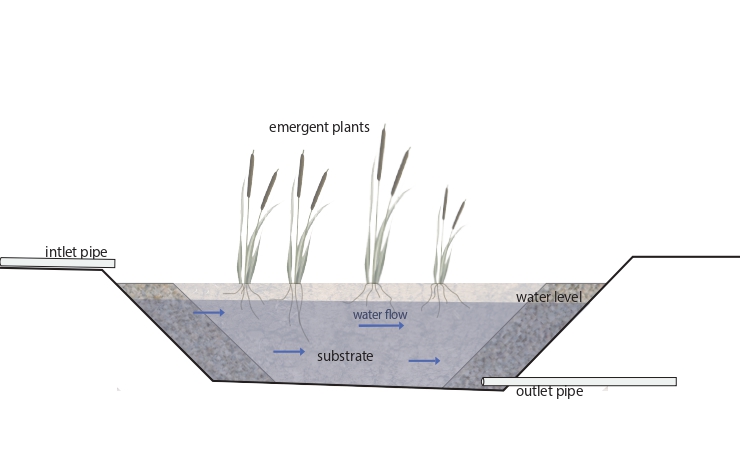

fig. 2: surface flow filter with substrate and emergent plants

Filters planted

In this model, the system works through percolation, meaning the wastewater infiltrates the substrate in the process of purification. Here the substrate can be saturated or not. [12]

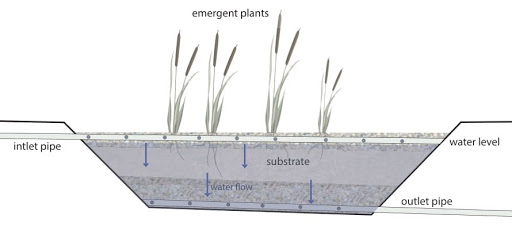

In this system, the water flows under the surface of the planted bed, through the pores of the substrate. There are two subsurface models: the horizontal flow filter and the vertical flow filter.

In the horizontal model, the flow can be operated in a continuous input, intermittent or even in batch mode whereas the vertical flow model requires intermittent dumping of water in short periods, followed by long resting intervals.

fig. 3: subsurface horizontal flow filter

The long periods between inflow in the vertical flow basin results in a high rate of oxygen transfer from the atmosphere to the system. In aerobic conditions the nitrification can occur, potentiating the nitrogen. In the horizontal flow basin, the poor levels of oxygen favor the occurrence of denitrification by anaerobic bacteria. [13]

fig. 4: subsurface vertical flow filter

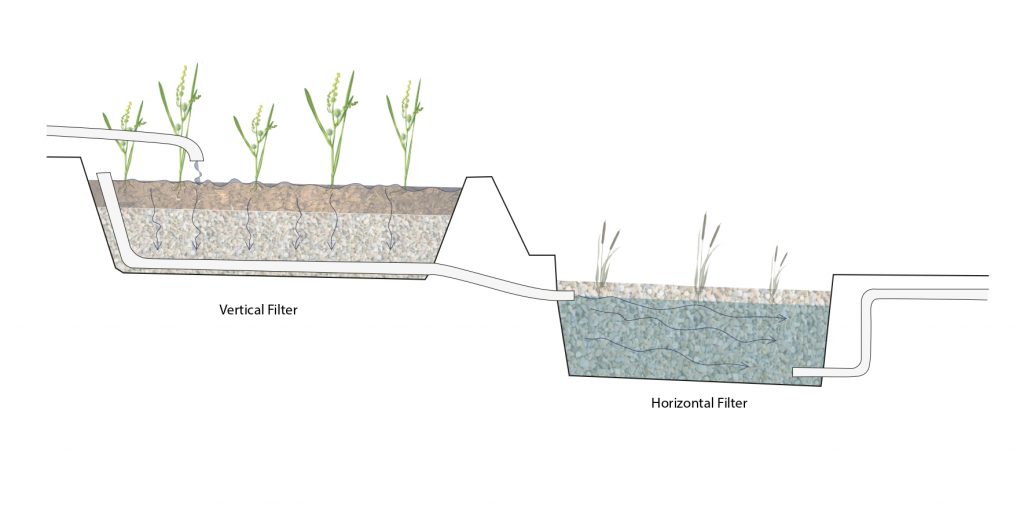

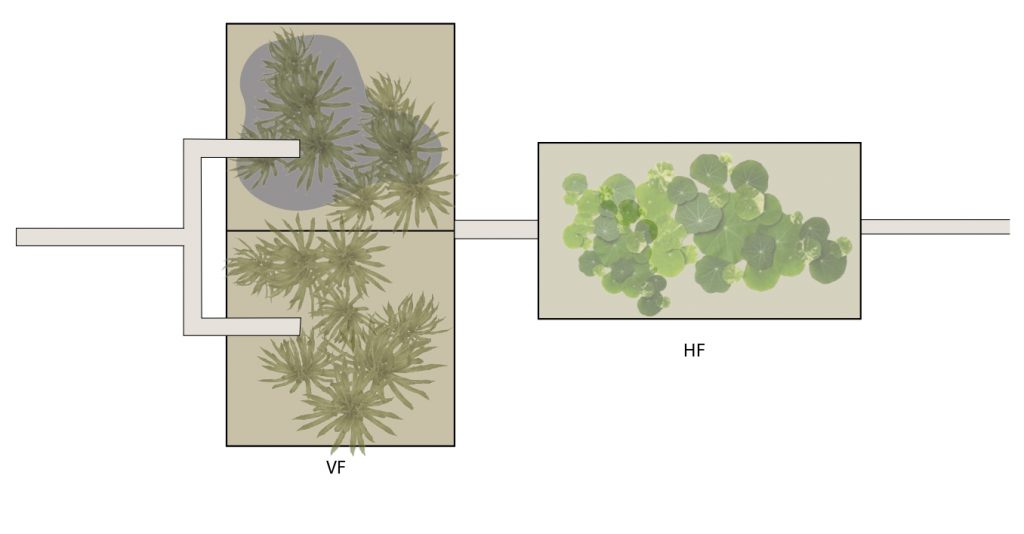

In some cases, both flows can be combined to enhance the system’s performance. That’s the case of the double planted filter method applied by Kevin Quentric and documented and published as a tutorial by low-tech lab. [14]

It consists of two different units with a vertical and a horizontal water flow that perform complementary tasks in the process of depurating the wastewater.

fig. 5: section of double filter planted

The first phase of this system is a 60-80 cm² deep vertical filter (VF) which is divided into two parts and each part takes turns receiving the raw sewage (wastewater without previous treatment) from above (see fig. 6). The wastewater spreads on the surface of the first filter and has its solid particles such as hair, fat, faeces, etc, drying and decomposing on the surface whereas the water infiltrates downwards until it reaches the gravel layer. It might sound like the perfect recipe for a smelly garden but, as Kévin explained in emails to us, in a nutshell, bad smells occur in warm, low oxygen environments, when the water stagnates and fermentation takes place. In this double filter planted, however, the vertical filter is in open air, meaning it’s fairly oxygenated. The coarse material retained on the surface of the sand dries out and compost whereas the wastewater quickly infiltrates, without time to ferment. For this, the occurrence of smells is rather rare.

After the percolation, the water then is collected by a drain in the bottom of the VF. This phase of the process is aerobic: the bacteria present in it require oxygen to mineralize the organic particles making the compounds absorbable by the plants.

fig. 6: plan of double filter planted

The second part of the system, the horizontal filter (HF) is 60cm deep, filled with gravel and water 10 cm below the substrate. The second filter is then a poorly oxygenated environment, in which anaerobic bacteria live. These bacteria perform the important task of denitrifying the water by extracting the oxygen from the nitrate molecules, turning them into dinitrogen.

Another interesting aspect is that this system is energetically autonomous. For that, it relies on gravity: each stage into the water purification is lower than the previous one so the water can flow without the use of pumps.

The step-by-step for this method can be found on the low-tech lab site. [15]

Pretreatment

In the double planted filter by Kevin Quentric there’s no need for primary treatment and the raw sewage can be discharged directly on the first filter. In some models, however, pretreatment is required before the wastewater discharge for removal of coarse particles and settleable solids in order to prolong the useful life of the systems, minimising the occurrence of clogging.

The specific type of pretreatment depends on the type of sewage and on the chosen method of phyto purification. Some of the primary treatment methods are:

Screening: This is typically the first step, especially for surface flow filters. Screens are used to remove large debris. [16]Oil removal by decantation: The method is based on injecting fine air bubbles into the grease tank, allowing the grease to rise quickly to the surface (grease is hydrophobic). [17]Sedimentation: Water is typically retained in sedimentation basins for at least 4 hours, allowing particles to settle out. [18]

Domestic phyto-purification

The management of wastewater is of extreme responsibility but depending on which system is chosen and the knowledge of the builders, self-construction is an accessible and plausible option. In addition, professionals in the field can provide help for those seeking to build their own phyto-purification system at home.

When planning a phyto-purification system, some things must be taken into consideration, such as sizing, site and botanical species.

Choosing a site

Ideally, the system should be located as close as possible to the sewage outlet. Remember to make sure the system works with gravity by building it on a slope or working with built and excavated basins. Earthwork is also an option but it might significantly increase the costs of the construction. In the elected site for construction, the soil should be sufficiently compacted to minimise groundwater infiltration and should be above the water table and floodplains.

Another aspect to have in mind is that phyto purification requires space. The site of construction should be of sufficient size to meet current and possible future expansions. Also, insects (especially on surface flow models) and, very rarely, odours can pose discomfort. Therefore, make sure the system is not too close to your and/or the neighbour’s house.

Lastly, the site should be very accessible to construction and maintenance machines and vehicles. [19]

Sizing

The dimensions of the system should be calculated by maximum capacity and a good way to do so is using the value of “inhabitant equivalent”, which relates to the house’s number of rooms and not to the number of inhabitants. In this model, each room of the house = inhabitant equivalent (2 to 4m²). [20]

Plants

To choose what species should be used, a few criteria need to be taken into consideration such as main pollutants to be removed; climatic conditions and local availability of species. They can be emergent, fluctuant or submerged species (see fig. 01). [21]

In Europe, the common reed (Phragmites communis) is one of the main wetland plant species used for water treatment, especially on subsurface flow filters. Some examples are Caltha palustris,Veronica beccabunga and the Typha latifolia.

fig. 7: Phragmites communis, Caltha palustris,Veronica beccabunga and Typha latifolia, respectively.

When the water goes through a pretreatment basin, the plants in the filter basin can be less resistant. Some examples are the Sparganium erectum, Alisma plantago and Iris pseudacorus. [22] Before mixing different species in the same basin, research about possible interactions between the species and if there is competition between them.

fig. 8: Sparganium erectum,Baldellia ranunculoides and Iris pseudacorus, respectively.

It’s advisable to transplant seedlings of plants that have been removed from a nearby location, which are naturally more adapted to the local climate and to do so in the rainy season, in order to minimise conditions of hydric stress for the plants. Plant the botanical species between 20 to 30 days before starting the purification system so there’s time for biological adaptation of the plants to the new environment.

Considering phyto purification

Phyto purification systems are economically efficient solutions. It is estimated that however the initial cost can be elevated (6.500 euros on the hybrid solution by Kevin Quendric, for example), these water treatment systems pay for themselves in about fifteen years time as they do not require electric energy nor maintenance by a qualified workforce.

Unlike conventional purification systems, phyto purification can support insects, birds, amphibians, contributing to the local biodiversity. The lack of chemicals makes the system an environmentally-friendly option available for water treatment.

In addition to environmental and economic upsides, planted filters can be a beautiful landscape project as it has an undeniable aesthetic value. A symbiotic relationship can emerge. The wastewater produced every day by humans is rich in nutrients valuable for certain plants of every shape and colour.

[1] Dias, Richardsson Mendes. (2019) Eficiência da Fitodepuração como Alternativa de Tratamento de Águas Residuárias: Um Estudo de Caso. Teresina: IFPI

[2]https://www.build-green.fr/phytoepuration-creer-un-filtre-plante/doing_wp_cron=1617567011.8170158863067626953125, accessed 4 April, 2021.

[3] Ibidem

[4] https://wiki.lowtechlab.org/wiki/Phyto%C3%A9puration_eaux_us%C3%A9es, accessed 5 April, 2021.

[5] https://www.lenntech.com/phytodepuration.htm, accessed 5 April, 2021.

[6] http://www.graia.eu/en/our-activities/phytodepuration-and-lagooning/, accessed 5 April, 2021.

[7]https://www.build-green.fr/phytoepuration-creer-un-filtre-plante/?doing_wp_cron=161756 7011.8170158863067626953125, accessed 6 April, 2021.

[8] Ibidem

[9]https://www.researchgate.net/publication/326352770_Manual_de_sistemas_de_Wetlands_construidas_para_o_tratamento_de_esgotos_sanitario_implantacao_operacao_e_manutencao, accessed 6 April, 2021.

[10] Ibidem

[11] Ibidem

[12]https://www.build-green.fr/phytoepuration-creer-un-filtre-plante/?doing_wp_cron=1617567011.8170158863067626953125 , accessed 8 April, 2021.

[13]https://www.researchgate.net/publication/326352770_Manual_de_sistemas_de_Wetlands_construidas_para_o_tratamento_de_esgotos_sanitario_implantacao_operacao_e_manutencao, accessed 8 April, 2021.

[14] https://wiki.lowtechlab.org/wiki/Phyto%C3%A9puration_eaux_us%C3%A9es, accessed 8 April, 2021.

[15] Ibidem

[16]https://www.sciencedirect.com/topics/earth-and-planetary-sciences/water-purification-plant, accessed 9 April, 2021.

[17]https://www.build-green.fr/phytoepuration-creer-un-filtre-plante/?doing_wp_cron=1617567011.8170158863067626953125, accessed 9 April, 2021.

[18] https://www.sciencedirect.com/topics/earth-and-planetary-sciences/water-purification-plant, , accessed 11 April, 2021.

[19https://wiki.lowtechlab.org/wiki/Phyto%C3%A9puration_eaux_us%C3%A9es, accessed 11 April, 2021.

[20] Ibidem

[21] https://www.researchgate.net/publication/326352770_Manual_de_sistemas_de_Wetlands_construidas_para_o_tratamento_de_esgotos_sanitario_implantacao_operacao_e_manutencao, accessed 11 April, 2021.

The post Phytodepuration with Degre.47 first appeared on Critical Concrete.

Did you miss our previous article…

https://www.akbarconcreteworks.com/?p=202

Knowing Our Food: Scraps

Picture the last food scrap you threw away. Maybe you were dumping some potato peels in the trash, or composting the outer leaves of a cauliflower. Why did you throw it away? Was it for aesthetic reasons? Did you consider any of that food inedible? Did you have patience in that moment to think of a reason to keep it? Were you out of containers to store it in? There are a multitude of reasons why food ends up in the bin, but we hope this article can make it easier to give your food (waste) another chance.

Food waste, as we’ve explored in this series on food knowledge, is one of the most urgent yet avoidable contributors to climate change. Even a single apple that goes to waste due to poor storage strategies or aesthetic imperfections represents a loss of all its embodied energy. That is to say, all the water and land used to grow it, all the energy used to transport and store it, and all of the caloric energy it could have provided to someone are squandered. At such a small scale, it’s negligible, and yet when everyone believes that throwing away food is not a big deal, it leads to enormous quantities of waste that often end up in landfills, releasing methane (a potent greenhouse gas) into the atmosphere.

Reframing Fruit Scraps

One way to reduce food waste is to rethink what you consider food. Of course, this isn’t to say that you should go around eating nut shells and parts of food that leave you with indigestion, but some foods that we are taught to discard have great flavors and health benefits.

On the most basic level, this applies to fruits with soft peels. Your apple, pear, peach, or nectarine skins can and should be eaten, but certain dessert recipes ask you to peel them, and in those cases, you can enjoy the peel by itself or use it in tea. Beyond those four, kiwi skin adds fiber and flavor when you eat it with the rest of the fruit, and dried pomegranate and hazelnut skin can be pulverized and added to smoothies or sprinkled on meals as a supplement. But fruit scraps don’t just have to be healthy; we highly recommend making treats out of your lemon and orange rinds. Although candied citrus rinds are great dipped in chocolate or sprinkled on cakes, the ones we made were devoured before they could make it to those stages.

More unusually, banana skins make a wonderful meat substitute in some recipes, like tacos or lasagna. Watermelon rinds make good pickles, but they can also be candied by cooking them in sugar syrup. If you make your own milk alternatives at home, you can use the strained almond, oat, rice, or cashew pulp for baking by replacing some of the flour in a recipe with pulp. (Be aware that milk pulp as a flour replacement will have an effect on the moisture and gluten content, so it only works in small ratios of pulp to flour and doesn’t work for difficult pastries, like croissants.) Another unusual recipe we tried was jam made out of passion fruit rinds. By boiling the rinds, taking the skin off, and mashing them with sugar, we cooked a slightly floral and astringent spread that goes well with bread or scones.

Vegetable Scrap Recipes

It’s helpful to rethink how you treat the scraps from your vegetables, too. Make sure not to waste delicious broccoli stalks or beet greens, and definitely don’t throw out the peels of your root vegetables. When a recipe requires peeled potatoes, the peels make a crispy snack or garnish when baked with some oil. Carrot greens transform into a delicious pesto when blended with oil, garlic, sunflower seeds, and salt.

Anything hard to chew can be blended into sauces, as is the case with kale stems and pea shells, and the stems of chard can be pickled. You can even sauté the tough green ends of leeks! The leaves of cauliflower, broccoli or romanesco broccoli should be cooked and eaten as well. Fava pods can be eaten whole, by grilling or sautéing them. When we tried out this recipe, we topped the pods with lemon juice, salt, chili flakes, and mint.

It should go without mentioning that any vegetable scraps can be made into broth. Herb stems are superb for this purpose, but celery, onions, leeks, carrots, potatoes, and celery root all provide scraps to flavor your broth. Sometimes, there isn’t enough waste to produce broth, so these scraps can be stored in the freezer while you collect enough.

Similarly to broth, parts of some foods can be added to teas or infused on their own. This is most true for leaves, especially artichoke, persimmon, and strawberry leaves, and for dried or fresh citrus rind.

Other Food Scrap Uses

Food scraps have purposes beyond just culinary! When making a vinegar-based cleaning solution for your house, lemon, orange and grapefruit rinds add a nice aroma. Banana skins serve as aphid repellents when they are chopped up and buried a couple inches deep around the base of a plant, and have anti-inflammatory properties when used on irritated skin. Coffee grounds and oat, almond and rice milk pulp are great body exfoliants, with rice and oat pulp having additional soothing properties when used on facial skin.

Many food scraps can be used to regrow foods, and these experiments double as educational projects as well. Root vegetables can be regrown by placing the tops of the root in water until new leaves begin to grow, at which point they can be planted in soil. Ginger pieces the size of an inch can be planted directly, and in very little time they will grow more ginger. Long, green vegetables such as celery, lemongrass, leeks, and green onions can be regrown by placing one inch of the bottom part of the plant (not counting the length of the roots) in a tray or glass of water until it begins to grow again. They can then be planted in soil. Leafy vegetables such as lettuce or endives undergo a similar process: the bottom parts are placed in water for several days or a few weeks until there is new growth and they can be moved to soil.

Scrap Dyes

We’ve saved the most exciting use for last: dyes! Many fruit and vegetable skins have tannins that help dyes bond well to natural fibers like cotton, linen, wool, or silk. The most well-known dyes made from food scraps are onion skins and avocado pits and skins. Yellow onion skins make yellow and orange dyes, red onion skins create colors between light lilac and deep magenta, and avocado scraps make a pink dye.

These dyes can be made stronger with alum powder, a mordant which helps dyes adhere to fabric better, but they can be used without it as well because of the presence of tannins in these food scraps. Some natural dyes, like the brown colors from chestnut and walnut shells, are vastly improved with the use of a mordant. Pomegranate rinds make a yellow dye and the leaves from loquat trees make a pink dye, both of which work best using a mordant.

Scraps in the Big Picture

Sometimes the scraps from your food just can’t be eaten or used, and that’s okay! When you get to this point, what’s most important is diverting your food waste from the landfill. If your city has a municipal composting program, you may have curbside compost pickup which is an easy way to reduce the emissions of your food waste, but you can also easily set up a compost in your own backyard, or get a small vermicomposting bin for your kitchen. Food waste can also be used to feed a biodigester, which produces biogas that you can use for energy. Both composts and biodigesters are part of our ongoing research at our production center, so you can expect an article soon about the merits and challenges of these systems in an urban setting. And lastly, if you do not have access to municipal or domestic compost where you live, you can see if any farmer’s markets or local gardens collect compost, and bring your food waste to them on a weekly basis.

When it comes to food, there are so many systemic and cultural barriers to consuming it mindfully and avoiding waste. Overcoming preconceptions about food scraps that are seen as non-food is one part of working against these entrenched cultural beliefs that promote excessive waste. The problem, like any environmental issue, does not come down to just personal choices, but when these small changes are implemented at a wide scale, they can have significant effects, not just in the amount of food that goes to waste, but towards treating the food we have with respect. When we stop taking food for granted, we respect the seasonality of our produce, and stop letting vegetables go bad due to poor storage. You can read about these two related practices in the previous articles of our Knowing Our Food trilogy, and learn about how to preserve food for long or short periods.

The post Knowing Our Food: Scraps first appeared on Critical Concrete.

Knowing Our Food: Storage

Though food nourishes us every day, there is still much that we can learn about it. At Critical Concrete, we aim to consume as much local, seasonal food as possible and we have recently started growing it ourselves in our food forest. Unfortunately, it is quite common that we as a society eat food without paying attention to its seasonal availability; it is easy to be influenced by a globalized system that makes practically any food available at any time in the year regardless of climate and the environmental impact. The production of food outside of its peak season can have 3-10 times the emissions as food imported from better climates, so it is important to not only support local farmers, but also to mind the seasonality of fruits and vegetables.[1] While some imported foods, such as almonds and avocados, are imported by boat and have a lower footprint than locally produced options, other more perishable foods are freighted by air, which creates 50 times the carbon emissions as boat transportation.[2] Aside from environmental friendliness, seasonal, local food can be more nutritious and flavorful as it has more time to ripen before harvest, and supports small farms and sustainable farming practices.

That being said, choosing local and seasonal produce means nothing if our food goes bad before we have the chance to eat it. That means that storing food to extend its lifespan is highly important. This research grew out of our curiosity to know more about alternative ways of storing food that are not energy consuming. However, as we encountered more information, the research evolved to focus more on food knowledge, with the aim of informing ourselves and our readers about the needs of our fruits and vegetables and how we can store and consume them. Our upcoming articles from this research will delve into the topics long-term storage, food production, and the use of food scraps, and in this article, we will discuss how to make use of conventional kitchen storage to keep food fresh.

Food Waste and the Fridge

Food waste is an immense problem that worsens each year. In fact, fighting food waste has been determined to be one of the most urgent solutions to fighting climate change.[3] The production and disposal of wasted food results in water waste, land waste and deforestation, and greenhouse gas emissions. Although a tremendous amount of food waste is the result of industrial food practices, in Europe 42% of food is thrown out by the consumer, and only one third of that food wasted consists of inedible residuals (skin, shells, peels).[4] Regardless of whether climate change can be tackled through individual actions, consumers can still reduce the amount of food lost to spoilage in their own homes. Even if it does not solve environmental issues in and of itself, when we learn about proper food storage and reduce our waste, we save money and take the first steps toward better societal food practices.

At first we were inclined to look for alternatives to our usual house appliances like the fridges, as refrigerants like chlorofluorocarbons (CFCs) are the main cause of the depletion of the ozone layer.[5] This led us to a few methods of long-term storage, which we built as prototypes to evaluate their efficacy in the climate our research lab is located in. Keep an eye out for our next article, detailing these methods and their benefits for different foods and environments.

However, it can’t be ignored that storing food in the fridge and freezer is such common practice, so this article will describe the ways to reduce food waste in the context of conventional storage practices. Thus we first have to analyse the way the fridge is used, to know its strong and weak points and the way it works. Additionally, it is crucial to understand the process of food decay and the science behind it. Once it is understood how food decays, the same principles can be applied everywhere. In order to reach a balance in the system, minimizing waste and prolonging the life of food, we must first know the needs of fruits and vegetables and demystify their storage environments, both artificial and natural.

Where to store different fruits and vegetables

Food Decay

Knowledge about everyday storage of fruits and vegetables is essential. In order to better understand the proper storage of fresh vegetables and fruits, the first step is to clarify the biochemical characteristics and processes which occur after harvesting. This knowledge can help reveal why certain foods become rotten very fast whereas other foods last for a long time. This phenomenon is influenced by two factors: the speed of natural metabolism depending on the specific plant and the way it is stored.

Enzymes are proteins which serve as catalysts to chemical changes in living organisms and there are thousands of different enzymes with varying functions. Enzymes in our food cause changes to fruit and vegetables which cause them to spoil. In cool temperatures, these enzymes slow their activity, and they can die when cooked above 60 degrees.[6]

Aside from enzymes, three other rotting agents can reduce the life of food. These are mold, which is visible, yeasts, which convert sugars into alcohol through fermentation, and bacteria, some of which can poison food.[7] Using this information, we can determine how to avoid mold and bacteria, and slow down the process of decay.

Conditions for storage

The best storage method for a given food depends primarily on three parameters: temperature, humidity and ripening.

Temperature: Cooling down slows down the metabolic process and thus has an immense effect on preservation. Nevertheless, there are certain plants, such as bananas, tomatoes, eggplants or cucumber which are very sensitive to the cold and also others which lose vitamins and taste.[8] Moreover you should take into consideration where in the refrigerator to put things. The middle and the back are usually colder than the other areas of the fridge.[9] As there is no cooling on the bottom cold air coming from the middle can warm up and rise up which leads to the different temperatures levels.[10]

Zones of the fridge and their temperatures

Humidity: Many fruits and vegetables, such as cucumbers, leafy greens, carrots and roots, are susceptible to humidity loss and shriveling.[11] For these, it is important to ensure a high level of atmospheric humidity. Many refrigerators have a crisper drawer for vegetables in order to keep a higher level of humidity. Some vegetables that should definitely be stored in the crisper drawer are spring onions, celery root, spinach, and leeks.[12] Otherwise, vegetables that are susceptible to moisture loss can be wrapped in damp towels and stored in other areas of the fridge.

Ripening: In basic terms, ripening can divide produce into two groups: the kind that continues the process of ripening after the harvest and the kind which abruptly stop ripening when harvested. This fact depends on the natural plant hormone ethylene. Ethylene is a gaseous hydrocarbon (C₂H₄) which speeds up the ripening process.[13] Some fruits and vegetables release ethylene gas in the process of becoming ripe.[14] Others, by contrast, are sensitive to ethylene and absorb it.[15] If you do not want to speed up the ripening and spoiling effect, try to store ethylene-sensitive vegetables apart from those which release a lot of ethylene.

Ethylene production and sensitivity in fruits and vegetables

According to their ethylene production, apples, tomatoes, peaches, apricots, avocados, kiwi, mango and bananas should be stored apart from other fruits and vegetables.[16] But you can also make use of this property when you want something to ripen faster. In that case, you purposefully store high ethylene producers together with ethylene sensitive ones.[17] When you have green tomatoes you can store them together with apples in order to get them to ripen faster.

Referring to proper storage, there are some rules of thumb about food that should never be stored in the refrigerator. Fruits sensitive to cold are pineapples, avocados, bananas, mandarins, mango and melons.[18] Vegetables sensitive to cold are artichokes, tomatoes, potatoes, eggplants, garlic and onions.[19] Nevertheless, there are some real divas who cannot really decide whether they want to be stored in the fridge or in the room. Cucumbers and zucchinis for example are sensitive to cold but if too warm they lose humidity and start to shrivel fast.[19] Therefore, they should be stored in the crisper drawer or in the top part of the refrigerator, wrapped in a damp towel to avoid cold damage and humidity loss.[20]

Additional Specific Storage Strategies

With this knowledge of general food storage, we can delve into more specific ways to increase the lifespan of our fruits and vegetables. Berries and cherries are susceptible to mold, so they should not be washed until just before they are eaten.[21] Also, berries are often quite fragile and should be stored in a single layer, if possible.[22] Figs are sensitive to humidity, which makes paper bags good storage containers to absorb their excess moisture, but they can also be stored on plates in the fridge.[23]

As for vegetables, removing rubber bands from the stems is always the first step.[24] Radishes, beets, carrots, and turnips, should be separated from their greens to avoid losing moisture in the roots.[25] Then, the roots can be stored in an open container with a wet towel placed on top.[26] Greens are best in closed containers alongside a damp cloth to keep them from drying.[27] However, you can save room in the fridge by storing kale, chard, and collard greens upright in glasses of water on the counter.[28] Celery and fennel can be stored this way as well.[29] Asparagus is best stored upright in a water inside the fridge.[30] It should be noted that using paper bags, reusable containers, glasses, or damp cloths should make it easy to eliminate the need for any single-use plastic inside the fridge.

Conclusion

Hopefully, being more cognisant of the needs of fruits and vegetables can limit food ending up in the trash or compost. Now that we understand how the chemical processes happening inside fruits and vegetables cause them to react to different conditions, we can store it in the right way. We can take advantage of the different areas inside your fridge, and organize our fridges to maximize the lifespan of our food. To help adjust to all this new information, we produced a chart to help understand fruits and vegetables and store them in the best way possible. Download it, print it, and put it on the wall in your kitchen!

In our next article about food we will discuss different ways to store food for longer periods of time and the benefits of each method. Stay tuned to learn how fruits and vegetables can be enjoyed past the periods when they are in season, without forfeiting the nutritional value and flavor of eating seasonal food.

VIEW AND SAVE OUR GUIDE![]()

Bibliography:

[1] https://ourworldindata.org/food-choice-vs-eating-local, opened 8.12.2020.

[2] Ibid.

[3] Hawken, Paul. Drawdown: The Most Comprehensive Plan Ever Proposed to Reverse Global Warming. New York, New York: Penguin Books, 2017.

[4] Principato, Ludovica. Food Waste at Consumer Level a Comprehensive Literature Review. Springer International Publishing, 2018. p. 5.

[5] https://www.conserve-energy-future.com/causes-and-effects-of-ozone-hole.php, opened 8th of December, 2020.

[6] Seymour, John. The Self-Sufficient Gardener: A Complete Guide to Growing and Preserving All Your Own Food. Dolphin Books, 1980.

[7] Ibid.

[8] https://www.rollende-gemuesekiste.de/wp-content/uploads/Lagertipps.pdf, opened 24.11.2020.

[9] Ibid.

[10] Ibid.

[11]

[12]https://myplasticfreelife.com/wp-content/uploads/images/Berkeley%20Farmers%20Market%20Tips%20for%20Storing%20Produce.pdf, opened 27.11.2020.

[13] https://www.theproducenerd.com/2018/02/what-is-ethylene-how-is-it-used/, opened 10.12.2020 December

[14] Ibid.

[15] Ibid.

[16] Sächsische Landesanstalt für Landwirtschaft. Verbraucherinformationen Obst Und Gemüse Richtig Lagern, 2003.

[17] https://www.rollende-gemuesekiste.de/wp-content/uploads/Lagertipps.pdf

[18]https://myplasticfreelife.com/wp-content/uploads/images/Berkeley%20Farmers%20Market%20Tips%20for%20Storing%20Produce.pdf, opened 27.11.2020.

[19] Ibid.

[20] Ibid.

[21] Ibid.

[22] Ibid.

[23] Ibid.

[24] Ibid.

[25] Ibid.

[26] Ibid.

[27] Ibid.

[29] Ibid.

[30] Ibid.

The post Knowing Our Food: Storage first appeared on Critical Concrete.

Did you miss our previous article…

https://www.akbarconcreteworks.com/?p=176

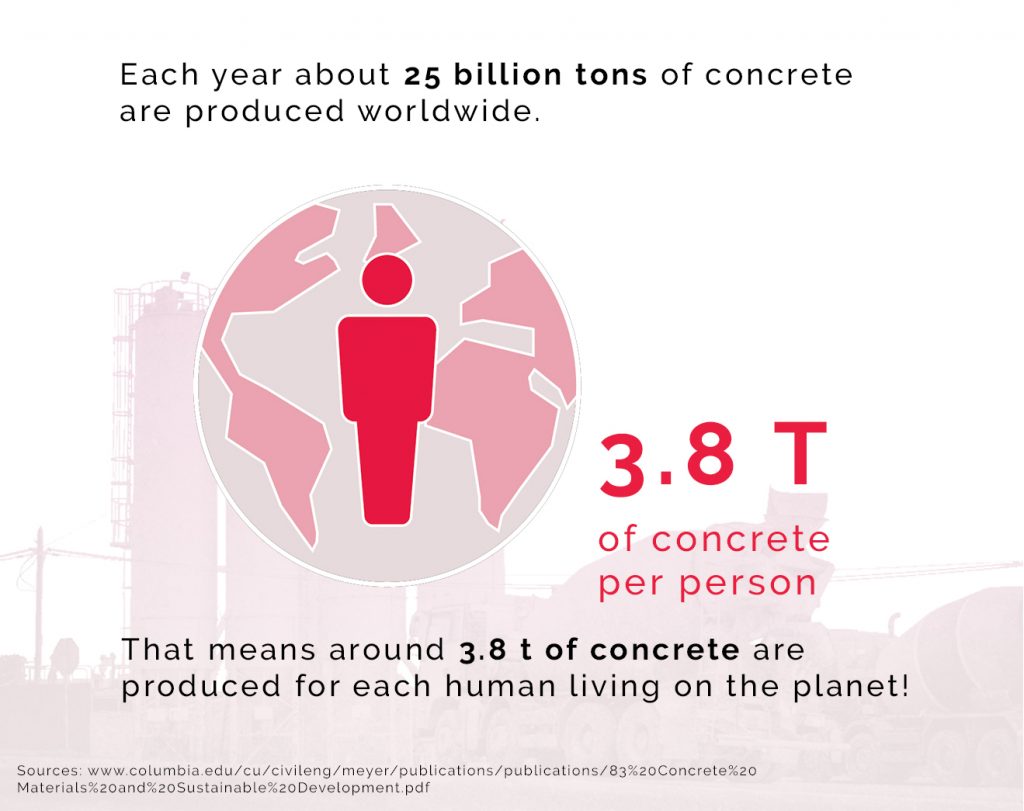

The reality of concrete

Looking for an alternative, sustainable way of practicing architecture? Apply now for our Postgraduate!

Concrete, as the most used building material worldwide has a huge impact on our cities, societies and environment. Much of our research is based on the idea to create an alternative solution for conventional methods of building, such as building with concrete. In this article, we will tackle basic and relevant knowledge and information about concrete, to understand why it is important to think about alternative solutions for the future of our building habits. This write-up will be part of a series of small papers related to meaningful knowledge, to understand why it’s urgent to rethink our conventional building approaches.

Concrete, cement & mortar – definitions

To give a brief overview of what we are talking about in specific, we will first define the most important terminologies that we will need to understand the whole topic around concrete.

Four important terms you should know about and understand their exact definitions:

Typical composition of concrete

cement // səˈment

Cement is the key ingredient to mix concrete. This product is mainly made out of crushed limestone mixed with shales and slates, shredded to a fine powder and heated up to approximately 1450°C. The heat causes a chemical reaction, also known as calcination.[1] That reaction along with the heating process causes a high amount of carbon-dioxide emissions, which makes cement production a big driver of greenhouse gas emissions. The entire process happens in a giant mixer, called a cement kiln. [2] The most popular kind of cement is portland cement, developed in England in the early 19th century. [3]

concrete // ˈkänˌkrēt

Concrete is an artificial building material, which consists of a binding agent like cement or lime, in addition to water and aggregates (sand and gravel) as well as potential additives (like fly ash or plasticizers). The cementitious part gets liquified with water. By adding water to the cement a chemical reaction is caused and the process of crystallization begins. In the next step some additives such as gravel and sand are added. These aggregates are held together by the liquified cement. Once the whole mixture is cured, this process will finish with a solidified product, called concrete.

mortar // ˈmôrdər

Mortar is a workable paste, used to bind bricks, stones or to fill gaps and holes. The basis is made out of a binding agent (such as slaked lime, ash or, most commonly nowadays, cement) added with water and a fine aggregate, mainly sand.

Mortar is one of the oldest building materials, used for many thousand years. For a long time, slaked lime, volcanic ashes or clay worked as a binding agent. During the nineteenth century portland cement was invented. From that time cementitious mortar rose in popularity and replaced the old binding products.

These two kinds of mortar differ in two ways. On the one hand cementitious mortars usually are more workable due to faster curing, higher water resistance and less cracking, on the other hand non-cementitious mortars significantly cut greenhouse emissions while processing. It even can absorb CO2, which appears to happen when lime mortar cracks, so that air (especially CO2) can be absorbed. By absorbing CO2, lime mortar is even molding and gets even stronger.[4] To put it plainly: it’s an environmentally friendly and more sustainable alternative.

reinforced concrete // ˈˌrēinˈfôrst ˈkänˌkrēt

In most cases concrete is combined with steel rebars, to compensate for the low tensile strength. The capability of concrete to react on compressive load is ten times bigger than the capability to bear tension loads.[5]

A more advanced and further developed version of conventionally reinforced concrete is prestressed concrete. To make concrete structures more durable against tensile forces, tendons, a high performing kind of rebar gets tensioned. Mainly these tendons are wires or threaded rebars. When applying in the casted concrete, the concrete part gets compressed, which gives the structure a higher performance, while being in service. [6]

Why is cement concrete so popular?

There are many reasons for its popularity: its liquid stone characteristics were revolutionary and created the possibility to make nearly every form out of concrete.

Cement concrete structures can be segmented and precast, making it suitable for big construction projects; and once solidified, it is a very strong material with the ability to bear high amounts of load. Designers adopted the versatile material, and nowadays we find furniture and accessories made of this material, in every kind of shape.

The use of concrete can be dated back to the ancient times. Romans mastered the use of hydraulic lime as a binding agent, called “opus caementicium”. After the fall of the Roman empire, the use of concrete faded, till it got resurrected in the early 19th century. Instead of using hydraulic lime, portland cement, a further development of the ancient version, was invented and led to a big rise in popularity of concrete in building industries. The first buildings during this time were bridges, foundations and harbours, facilitated by the compressive strength and workability of the new material.[7]

In the late 19th century iron rods, and later steel rebars, were added to poured concrete to increase tensile strength. It was mainly developed by the French Joseph Monier [8] – an invention which is ubiquitous in building industries nowadays. This invention led to a big rise in popularity in the residential and social housing sector. In comparison to conventional houses in those days, new concrete based housing projects were more durable, termite and fire resistant. The workability of concrete made it fast and easy to use on site. Pre-castable and serial development of construction elements cut costs significantly. In the 50s of the last century, concrete played a major role in evolving the architectural style of Brutalism, a socio-aesthetically driven architecture movement of showing raw, honest constructions often used for big scale civic and public projects. This architectural style was a dominating force during the next two decades. [9]

In addition, the raw materials of concrete are available in large quantities around the globe, which makes concrete cheap to produce. Limestone, sand and gravel are quite cheap. The main processing costs are caused by the cement production.

What quantity of resources are needed to produce cement concrete?

There are four main components of cement concrete (cement, water, sand and gravel). For reinforced concrete, there is an additional component – steel. Besides these materials, there are more raw resources needed to produce the main ingredients. To produce one tonne of cement, approximately two tonnes of raw limestone are necessary. [10] The production of cement is a high energy consuming process. One ton of cement takes about 120 kWh of energy in process heating. This energy is mainly obtained from fossil fuels and burning waste. [11]

The cement concrete recipe

There are several different recipes for making concrete. The recipes mainly differ in the ratio of cement and the added aggregates. Concrete can be mixed with different ratios to get a higher load bearing capacity or to get a higher ability to withstand different exposures, such as seawater, moisture or frost.

The following recipes just give you a basic overview about how a classic mixture of concrete could look like:

A standard concrete mix consists of 1 part water (7,7%), 2 parts cement (15,4%) , 4 parts sand (30,7%) and 6 parts gravel (46,1%). [12]

The higher the load the more cement you’ll need (f.e. a concrete column, foundation needs 1 part water (11,1%), 2 parts cement (22,2%), 2 parts sand (22,2%) and 4 parts gravel (44,4%) ).

Around 70% of the built concrete constructions are reinforced with steel, so you would usually have to add a certain percentage of steel rebars to the produced concrete (60-80 kg/m3 of concrete).[13]

That means a ton of average concrete consists of:

77 kg of water (7,7%)154 kg of cement (15,4%)307 kg of sand (30,7%)461 kg of gravel (46,1%)

Components of 1 tonne of concrete

Where is concrete used?

The use of cement concrete has various fields of application in construction and design. Since it was developed in the early XIXth century as a powerful structural material, it can be found in several constructive elements. The constructive elements made out of concrete can be summed up in three main categories:

massive built horizontal and vertical load bearing elements such as foundations and walls, used for small to middle scale buildings, such as residential housing.filigree skeleton construction elements, such as pillars and beams, mainly found in high rise buildings and large scale commercial buildingsspecial construction elements for infrastructural and exceptional building typologies, such as bridges, tunnels, dams or bunkers.

Where is concrete useful?

Nowadays concrete is used in many different ways. All constructive elements can be made in concrete and in most cases they are realized with this material.

But is it really necessary to replace other common construction methods with concrete?

It makes sense to use concrete in constructions, where load bearing elements have to bear big compressive strengths. A high rise a few hundred meters high? A tunnel? A dam? For sure! – There are fields of application, where no other material performs as well as concrete but in many cases concrete is used in small scale projects, where it is unnecessary and over proportioned.

How sustainable is cement concrete?

Concrete is certainly one of the building materials which gives a nearly unlimited range of use. As mentioned before, there are many upsides to using concrete. But there are always two sides of the coin.

A general definition for sustainability is meeting the needs of the present without compromising the ability of future generations to meet their needs. Sustainability is often discussed in environmental terms. It can also be related to two other important topics: society and economy.

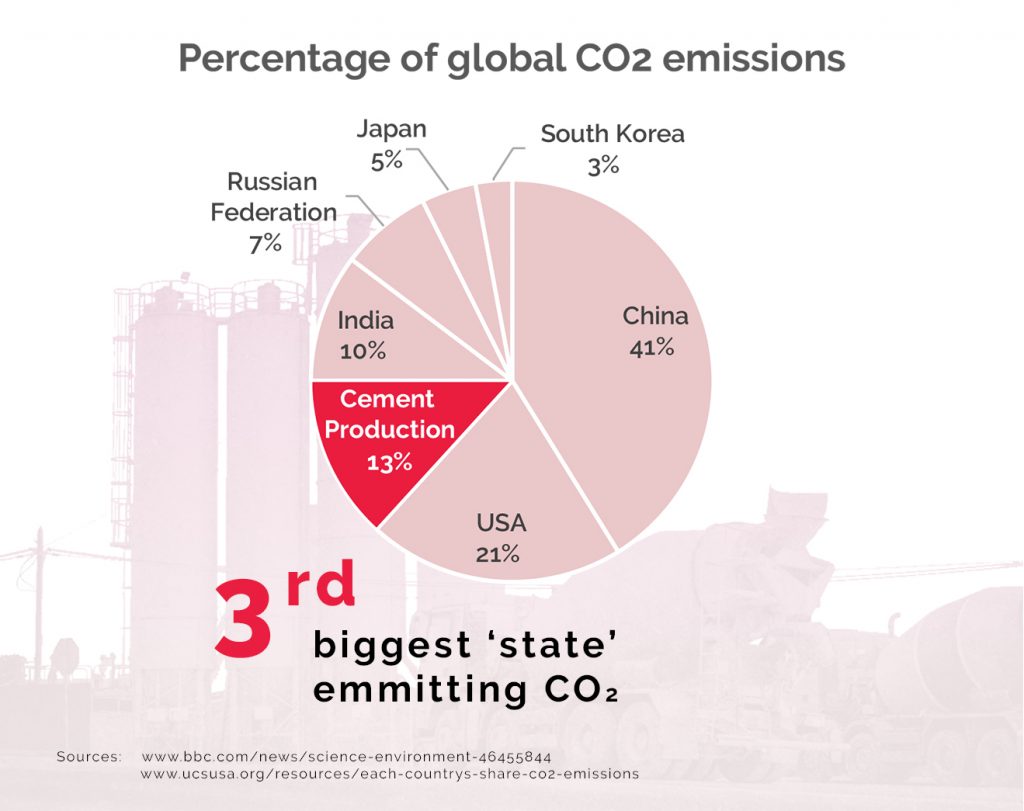

Obvious and hidden impacts on our environment

Pie chart comparison between countries CO2 emissions and cement production

The impact on our environment caused by the cement industry and by building with concrete is enormous. The production of cement is a high energy consuming process. This energy is mainly obtained from fossil fuels or burning waste [14] In addition the chemical process of producing cement releases one molecule of carbon-dioxide per each molecule of calcium silicate hydrate. For each ton of produced cement, one ton of CO2 is emitted just by chemically processing it [15] Besides the vast amount of carbon dioxide emitted, many other hazardous air pollutants such as NOX or PM10 are emitted during the process. [16]

Cement is just one part of concrete. The added aggregates, such as gravel and sand, are mined in humongous amounts to cover the demand of concrete industries. Many environmental systems are suffering from negative effects such as land loss by erosion, destruction of natural habitats, sealing and contamination of soil. Some of these aggregates, especially sand, have to be shipped around the world to service demands. [17] Just to give a short glimpse of one of the biggest cruxes in world of the concrete industries – new developing middle-east states, such as the United Arab Emirates or Qatar have to import big amounts of sand to service their huge demand in building industries, despite the fact that cities like Dubai or Qatar are located in the middle of sandy deserts. [18] However, not all of the sand we can find on the globe is suitable for concrete production; desert sand is too fine and round to be used as an aggregate. [19]

Furthermore, concrete production is a thirsty industry. It needs almost 10% of annual industrial water withdrawal, and 75% of the concrete production takes place in regions which are already facing water stress and drought. [20]

Beside this, the impact on society has to be emphasized. The internationalization of architecture and modern building technologies have a negative influence on vernacular building technologies and local architecture. New buildings tend to be built in a modern way with modern materials, such as concrete. Cost efficiency, the establishment of new building technologies and the time aspect are reasons for a significant decrease of traditionally built projects.

Impact of globalization and industrialisation on building traditions.

Comparison between the use of concrete and other building materials

One of the main issues caused by that situation is the loss of building knowledge and traditions. Traditional building techniques are being replaced by modern approaches. Around the world, houses and cities have been built according to local tradition for centuries. Now, knowledge that was gained in a long and enduring process is about to get lost in a few decades.

Main drivers for the loss of vernacular architecture are caused by the growing globalization and industrialization of the world. Innovations in building technologies can be spread easily around a fully connected world. Rare materials not locally available can be easily shipped from anywhere – and they get transferred in humongous amounts around the planet.

Downcycling cement concrete

The economic sustainability of concrete is always mentioned as a big pro. Nonetheless there are a few facts which are not properly taken into consideration. The production of concrete is cheap in comparison to other materials. A main reason for this, is that the aggregates you need to mix concrete are available in large quantities almost everywhere around the planet. But in recent times the local availability of certain components, such as sand are diminishing. [21] Our resources on the planet are finite, so using and monetizing resources as if they are infinite is unsustainable. To address this, the concrete industry tries to emphasize their product as recyclable, but to make it clear – concrete is not recyclableRecycling means, returning a material into a previous stage of a cyclic process. In case of the mentioned material, this is not completely possible. During calcination, the processing of the raw resource of limestone comes to a point of no return. Once cement is made, the process is irreversible. There is no commercially viable process to recycle it.[22] Recent reusing methods of concrete consist of shredding it and mainly using it as gritting material for infrastructural projects. In some cases this crushed concrete can be used as an aggregate to partly substitute gravel in concrete. Nevertheless these substitutes are small in numbers and in the end new concrete still requires additional water, cement, sand and gravel [23] Technically, the recent approaches to recycling concrete can be better named downcycling processes or a kind of mitigation. Many experts criticize the bigger potential of reusing shredded concrete for new concrete projects, [24] an effort which should be broadened in the future.

Contradictive durability of concrete structures

Many proponents often mention concretes’ durability as a big pro. The use of concrete without adding any other materials (such as rebars, made out of metal) technically creates a very durable building material. Despite, most of the applied concrete is reinforced to be able to react on tensile stress. But the application of reinforced concrete in terms of durability is a contradiction in terms. Here nature inevitably can shorten the life span of buildings built out of reinforced concrete. Due to different thermal expansions and the inevitable inheritation of oxidation of the used steel rebars, concrete constructions suffer fast deterioration during their lifespan. Recent studies have shown that there is a 50% chance of reinforced concrete structures to not fulfill their service in terms of load bearing after just 35 years of use. [25]

What can be used instead of cement based concrete?

Concrete as a kind of fluid stone has found use in all fields of construction. But is it always necessary to use concrete? There are new materials and also tried and trusted methods of building which have mostly been replaced by concrete solutions. The replacement of conventional portland cement based concrete can cut greenhouse gas emissions and other environmental impacts significantly. Basically there are two main ways to avoid a humongous use of classic portland cement based concrete. The first one is to substitute or avoid the most polluting ingredient of classic concrete, portland cement. In a second scenario different building approaches with alternating materials or other building techniques can be applied.

Cement substitutes

First of all, portland cement based concrete mostly can be substituted by pulverized fly ash (PFA), which is a side product of coal burning processes. Another substitute with a big potential is Ground Granulated Blast-furnace Slag (GGBS), which is able to replace portland cement up to 90%. GGBS substituted concrete sets more slowly than concrete made with ordinary portland cement. The higher the amount of GGBS in the cement mix the longer it takes to cure. Besides this, a positive side effect of using GGBS substituted concrete is that it continues to gain strength over a longer period leading to improved overall durability and life expectancy. [26] Nevertheless the mentioned substitutes are by-products of other industries, such as coal, steel or aluminium production, which also have an enormous negative impact on our environment.

Green concrete

During the last decade several scientists started working on green alternatives for concrete. The most advanced approaches use micro organisms such as algae, bacteria or fungi for biocement production (CaCO3) by using the metabolic activity of these microorganisms. [27,28] Some of these bioproducts achieve similar specifics as classic portland cement and present a feasible and viable alternative to conventional portland cement based concrete.

lternative construction methods

Besides an ingredient-related replacement of conventional concrete, there are many tried and trusted construction methods which were applied in vernacular building styles and local architecture traditions. There is no convincing evidence that justifies concrete as the ultimate building material for most building tasks.

This table aims to present a series of more ecologically friendly solutions for common uses of cement concrete:

construction elementclassic building material

to be replaced / substitutedeco friendly alternative (not exhaustive)foundationsreinforced concretetyre foundation (for point foundations) [29]

gabion foundations [30]pillarsreinforced concrete

steelwooden constructions (bamboo, pine, GLT – glue laminated timber)

cardboard tubeswalls(reinforced) concrete

bricks

steel sandwich panelswooden constructions (CLT – cross laminated timber, framework constructions)

rammed earth (clay)

hempcrete

bricksflooringcement based screedclay

wooden planks roofsreinforced concrete (flat roofs)

steel sandwich panelswooden constructions

thatched roofs

green roofs

hempcretepathingcement based pavement

asphaltnatural stone :

cobblestone, granite plastergypsum based plaster

cement based plastercardboard + lime plaster [31]

hempcrete plaster

straw clay based plaster

Conclusion

Concrete plays a major role in building industries. The further development of newly industrializing economies with huge demands on concrete are driving the ongoing trend of a growing concrete industry. Beside its advantages and big popularity, concrete brings a lot of negative impacts on global warming, environmental systems, building culture and social city development. It is important to mention that concrete lacks recyclability. The present system around the concrete industry can be summed up as a cradle-to-grave system. Resources are extracted, used and then wasted and dumped or downcycled in the best case scenario. Due to the chemical process, cement, the most important ingredient of conventional concrete, will never be recyclable, which underlines the unsustainability of a whole industry. Its fast and wide availability and low costs in production make it popular for many large scale projects.

Nevertheless there are recent approaches to develop more sustainable alternatives to the classic portland cement-based concrete by trying to avoid or minimize the use of cementitious components, aiming for a better reusability and recyclability of resources.

In addition, investigating forgotten vernacular solutions reopens fields of research to move forward to a more environmentally respectful architecture. Stay tuned on our continuous research, on social media and if you can and feel like supporting the initiative, make a small donation on our Patreon!

Sources

[1] https://www.sciencedirect.com/science/article/pii/B978008034720250023X , opened 12.08.2020

[2] https://www.britannica.com/technology/cement-building-material/Extraction-and-processing , opened 12.08.2020

[3] https://www.screedscientist.com/portland-cement-a-brief-history/ , opened 18.08.2020

[4] Quantitative Analysis of CO2 Uptake and Mechanical … – MDPIwww.mdpi.com › pdf , opened 23.09.2020

[5] https://diglib.tugraz.at/download.php?id=576a7195cc9f9&location=browse , opened 11.08.2020

[6] 372R-13 Guide to Design and Construction of Circular Wire-and-Strand-Wrapped Prestressed Concrete Structures , 2013

[7] Historic Concrete in Scotland Part 1: history and Developmentpub-prod-sdk.azurewebsites.net › api , opened 13.08.2020

[8] https://www.britannica.com/biography/Joseph-Monier , opened 13.08.2020

[9] https://www.architectureanddesign.com.au/features/list/a-look-at-brutalist-architecture , opened 20.08.2020

[10] http://ecosmartconcrete.com/?page_id=208 , opened 12.08.2020

[11] https://global-recycling.info/pdf/GLOBAL-RECYCLING_2-2019 , opened 11.08.2020

[12] https://www.marshalls.co.uk/gardens-and-driveways/blog/how-to-mix-cement-to-make-mortar-or-concrete

[13] https://diglib.tugraz.at/download.php?id=576a7195cc9f9&location=browse , opened 26.07.2020

[14] https://global-recycling.info/pdf/GLOBAL-RECYCLING_2-2019 , opened 11.08.2020

[15] http://ecosmartconcrete.com/?page_id=208 , opened 12.08.2020

[16] http://ecosmartconcrete.com/?page_id=208 , opened 13.08.2020[1] http://ecosmartconcrete.com/?page_id=208 , opened 13.08.2020

[17] https://www.globalconstructionreview.com/news/shifting-sands-concrete-hungry-singapore-orders-mi/ , opened 28.07.2020

[18] https://www.bbc.com/worklife/article/20160502-even-desert-city-dubai-imports-its-sand-this-is-why , opened 19.08.2020

[19] https://www.bbc.com/worklife/article/20160502-even-desert-city-dubai-imports-its-sand-this-is-why , opened 19.08.2020

[20] https://www.nature.com/articles/s41893-017-0009-5.epdf , opened 26.07.2020

[21] https://www.globalconstructionreview.com/news/shifting-sands-concrete-hungry-singapore-orders-mi/ , opened 29.07.2020

[22] CSI-RecyclingConcrete-FullReport.pdf , opened 29.07.2020