Depurating Landscape: an introduction to plants as a water treatment alternative

This article is a collaboration between Degré47 and Critical Concrete, aiming to be an introduction to phyto purification’s general concepts for self-constructors. It also aims to shed light on these systems as low-cost, low-tech and self-constructible wastewater treatment solutions.

The wastewater issue

It isn’t new to argue that the disorganized and centralized population growth in urban areas has brought challenges to the natural environment. In addition to CO₂ emissions, waste production and impermeabilization of soil, wastewater is one of the fundamental issues local governments need to address. At the very least, the wastewater from human activities of any sort needs to be treated to be assimilated by nature.

There are many water treatment solutions, from the collective to the individual scale. One of the most common sanitation solutions in urban centres is a collective one: wastewater treatment plants. These centres manage the wastewater through physical, chemical and biological processes in a complex and highly specialized infrastructure. [1]

After the physical filtration through decantation, flotation, filters and/or membranes, traditional treatments commonly make use of chemical products, notably coagulants (ferric chloride, aluminium sulphate, etc.), flocculants, and sometimes disinfectants such as chlorine or ozone. These processes, however, are arguably costly and energy-intensive, not to mention polluting. They also necessarily generate by-products such as coarse waste, sand and sludge that must be cleaned, decanted, stabilised and treated. [2]

In addition, in the ever-growing urban centres, many areas aren’t able to access the public sewage system, bringing up the importance to think of alternatives for wastewater treatment, especially low-cost and low-maintenance ones, as the mismanagement of effluents can pose a serious issue to natural hydric resources. [3]

Individual or small-scale collective sanitation solutions might be a good way to tackle the situation. A solution that stands out is the phyto-purification system with its low energy and low maintenance (as there’s no need for emptying and transporting). It is already the main sanitation system in France for cities of less than 1,000 inhabitants. [4]

This system, which is based on the use of plants (phyto) to filter the wastewater has been proving to be a low-cost yet highly efficient way to treat domestic wastewater. Because it is energetically and logistically autonomous, phyto-purification can be considered an ecological sanitation solution.

Purification with plants

Phyto-purification consists of wastewater purification systems that make use of aquatic plants, reproducing water depuration processes typical of humid areas. There are two main methods of phyto purification: lagooning, which consists of ponds with microphytes, similar to natural wetlands, and the filters planted that make use of macrophytes and consist of ponds filled with aggregates in which the water circulates for treatment. [5]

In these systems, the plants are responsible for bringing oxygen through their roots whereas the aggregates act not only as a physical filter — as bigger particles can’t penetrate it — but also as a chemical filter as they absorb phosphorus and ammoniacal nitrogen. In these basins, an important biological process also occurs: the microfauna present in the system degrades organic matter, turning it into nutrients to be absorbed by the plants. [6]

The interesting aspect is that, although the name might indicate, the wastewater is not filtered by the plants. In reality, the plants are the key element to create the environment for bacterial activity, especially in the region around the plants’ roots. The plants greatly benefit from the system as it absorbs nutrients that are liberated in the process of depuration. It’s a symbiotic relationship.

The different methods

There are two groups of phyto purification systems that can be used according to different needs and types of wastewater: lagooning and filters planted. [7]

Lagooning

This system makes use of microphytes (small aquatic plants), microorganisms and (sometimes) substrate to control water pollution. Its main characteristic is the resemblance with natural wetland areas in which the majority of elements are saturated, i.e submerged in water. [8]

In this model, the main purification process occurs on the aquatic surface where the plants and the bacteria present in their roots are located. In this solution, the effluent is continuously supplied and homogeneously distributed on the surface, flowing horizontally and superficially at low scooping velocity. The water is then collected by a drainage pipe located in the basin’s bottom. [9]

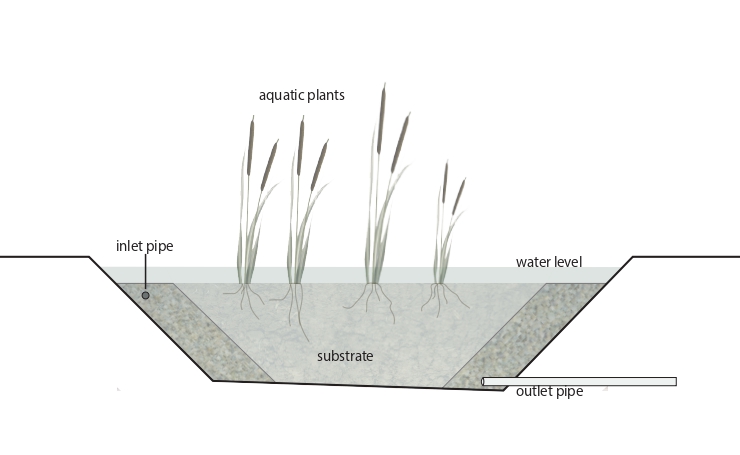

It is important to stress that in this solution, the substrate is not a requirement, and when not applied, fluctuant aquatic species should be used (see image 1). [10]

fig. 1: Different types of plants

Because there’s no emphasis on physical filtration with a substrate, this solution requires a previous treatment focused on the removal of organic matter and suspended solids as it mainly targets the removal of nutrients, especially phosphorus by the plants and bacteria. [11] The use of a substrate, however, can be beneficial if residual suspended solids end up in the basin.

This is a cheap and very low maintenance option, however, it generally requires a larger area than other methods.

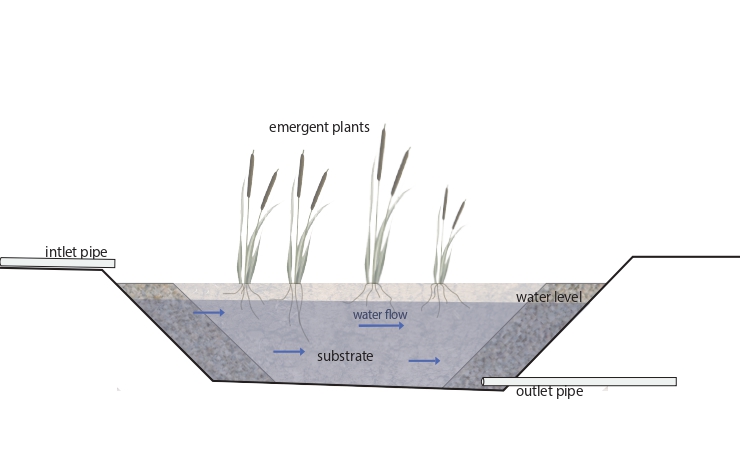

fig. 2: surface flow filter with substrate and emergent plants

Filters planted

In this model, the system works through percolation, meaning the wastewater infiltrates the substrate in the process of purification. Here the substrate can be saturated or not. [12]

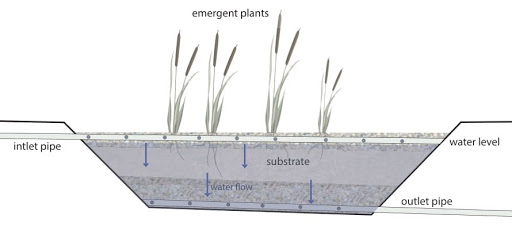

In this system, the water flows under the surface of the planted bed, through the pores of the substrate. There are two subsurface models: the horizontal flow filter and the vertical flow filter.

In the horizontal model, the flow can be operated in a continuous input, intermittent or even in batch mode whereas the vertical flow model requires intermittent dumping of water in short periods, followed by long resting intervals.

fig. 3: subsurface horizontal flow filter

The long periods between inflow in the vertical flow basin results in a high rate of oxygen transfer from the atmosphere to the system. In aerobic conditions the nitrification can occur, potentiating the nitrogen. In the horizontal flow basin, the poor levels of oxygen favor the occurrence of denitrification by anaerobic bacteria. [13]

fig. 4: subsurface vertical flow filter

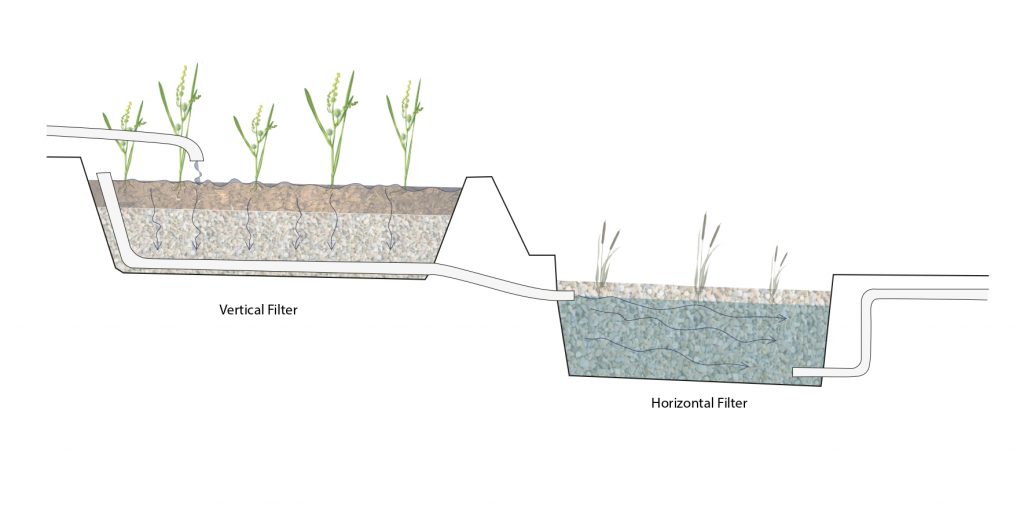

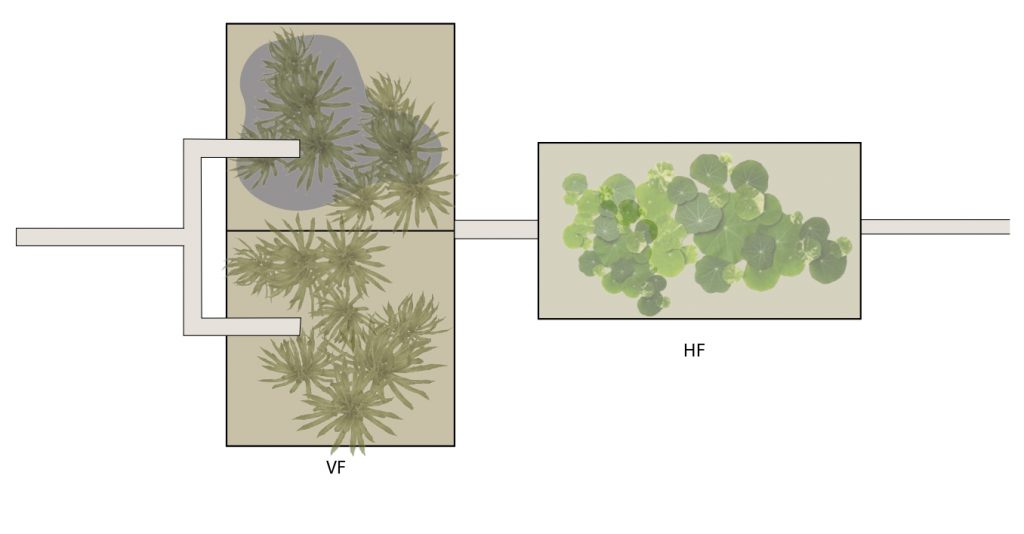

In some cases, both flows can be combined to enhance the system’s performance. That’s the case of the double planted filter method applied by Kevin Quentric and documented and published as a tutorial by low-tech lab. [14]

It consists of two different units with a vertical and a horizontal water flow that perform complementary tasks in the process of depurating the wastewater.

fig. 5: section of double filter planted

The first phase of this system is a 60-80 cm² deep vertical filter (VF) which is divided into two parts and each part takes turns receiving the raw sewage (wastewater without previous treatment) from above (see fig. 6). The wastewater spreads on the surface of the first filter and has its solid particles such as hair, fat, faeces, etc, drying and decomposing on the surface whereas the water infiltrates downwards until it reaches the gravel layer. It might sound like the perfect recipe for a smelly garden but, as Kévin explained in emails to us, in a nutshell, bad smells occur in warm, low oxygen environments, when the water stagnates and fermentation takes place. In this double filter planted, however, the vertical filter is in open air, meaning it’s fairly oxygenated. The coarse material retained on the surface of the sand dries out and compost whereas the wastewater quickly infiltrates, without time to ferment. For this, the occurrence of smells is rather rare.

After the percolation, the water then is collected by a drain in the bottom of the VF. This phase of the process is aerobic: the bacteria present in it require oxygen to mineralize the organic particles making the compounds absorbable by the plants.

fig. 6: plan of double filter planted

The second part of the system, the horizontal filter (HF) is 60cm deep, filled with gravel and water 10 cm below the substrate. The second filter is then a poorly oxygenated environment, in which anaerobic bacteria live. These bacteria perform the important task of denitrifying the water by extracting the oxygen from the nitrate molecules, turning them into dinitrogen.

Another interesting aspect is that this system is energetically autonomous. For that, it relies on gravity: each stage into the water purification is lower than the previous one so the water can flow without the use of pumps.

The step-by-step for this method can be found on the low-tech lab site. [15]

Pretreatment

In the double planted filter by Kevin Quentric there’s no need for primary treatment and the raw sewage can be discharged directly on the first filter. In some models, however, pretreatment is required before the wastewater discharge for removal of coarse particles and settleable solids in order to prolong the useful life of the systems, minimising the occurrence of clogging.

The specific type of pretreatment depends on the type of sewage and on the chosen method of phyto purification. Some of the primary treatment methods are:

Screening: This is typically the first step, especially for surface flow filters. Screens are used to remove large debris. [16]Oil removal by decantation: The method is based on injecting fine air bubbles into the grease tank, allowing the grease to rise quickly to the surface (grease is hydrophobic). [17]Sedimentation: Water is typically retained in sedimentation basins for at least 4 hours, allowing particles to settle out. [18]

Domestic phyto-purification

The management of wastewater is of extreme responsibility but depending on which system is chosen and the knowledge of the builders, self-construction is an accessible and plausible option. In addition, professionals in the field can provide help for those seeking to build their own phyto-purification system at home.

When planning a phyto-purification system, some things must be taken into consideration, such as sizing, site and botanical species.

Choosing a site

Ideally, the system should be located as close as possible to the sewage outlet. Remember to make sure the system works with gravity by building it on a slope or working with built and excavated basins. Earthwork is also an option but it might significantly increase the costs of the construction. In the elected site for construction, the soil should be sufficiently compacted to minimise groundwater infiltration and should be above the water table and floodplains.

Another aspect to have in mind is that phyto purification requires space. The site of construction should be of sufficient size to meet current and possible future expansions. Also, insects (especially on surface flow models) and, very rarely, odours can pose discomfort. Therefore, make sure the system is not too close to your and/or the neighbour’s house.

Lastly, the site should be very accessible to construction and maintenance machines and vehicles. [19]

Sizing

The dimensions of the system should be calculated by maximum capacity and a good way to do so is using the value of “inhabitant equivalent”, which relates to the house’s number of rooms and not to the number of inhabitants. In this model, each room of the house = inhabitant equivalent (2 to 4m²). [20]

Plants

To choose what species should be used, a few criteria need to be taken into consideration such as main pollutants to be removed; climatic conditions and local availability of species. They can be emergent, fluctuant or submerged species (see fig. 01). [21]

In Europe, the common reed (Phragmites communis) is one of the main wetland plant species used for water treatment, especially on subsurface flow filters. Some examples are Caltha palustris,Veronica beccabunga and the Typha latifolia.

fig. 7: Phragmites communis, Caltha palustris,Veronica beccabunga and Typha latifolia, respectively.

When the water goes through a pretreatment basin, the plants in the filter basin can be less resistant. Some examples are the Sparganium erectum, Alisma plantago and Iris pseudacorus. [22] Before mixing different species in the same basin, research about possible interactions between the species and if there is competition between them.

fig. 8: Sparganium erectum,Baldellia ranunculoides and Iris pseudacorus, respectively.

It’s advisable to transplant seedlings of plants that have been removed from a nearby location, which are naturally more adapted to the local climate and to do so in the rainy season, in order to minimise conditions of hydric stress for the plants. Plant the botanical species between 20 to 30 days before starting the purification system so there’s time for biological adaptation of the plants to the new environment.

Considering phyto purification

Phyto purification systems are economically efficient solutions. It is estimated that however the initial cost can be elevated (6.500 euros on the hybrid solution by Kevin Quendric, for example), these water treatment systems pay for themselves in about fifteen years time as they do not require electric energy nor maintenance by a qualified workforce.

Unlike conventional purification systems, phyto purification can support insects, birds, amphibians, contributing to the local biodiversity. The lack of chemicals makes the system an environmentally-friendly option available for water treatment.

In addition to environmental and economic upsides, planted filters can be a beautiful landscape project as it has an undeniable aesthetic value. A symbiotic relationship can emerge. The wastewater produced every day by humans is rich in nutrients valuable for certain plants of every shape and colour.

[1] Dias, Richardsson Mendes. (2019) Eficiência da Fitodepuração como Alternativa de Tratamento de Águas Residuárias: Um Estudo de Caso. Teresina: IFPI

[2]https://www.build-green.fr/phytoepuration-creer-un-filtre-plante/doing_wp_cron=1617567011.8170158863067626953125, accessed 4 April, 2021.

[3] Ibidem

[4] https://wiki.lowtechlab.org/wiki/Phyto%C3%A9puration_eaux_us%C3%A9es, accessed 5 April, 2021.

[5] https://www.lenntech.com/phytodepuration.htm, accessed 5 April, 2021.

[6] http://www.graia.eu/en/our-activities/phytodepuration-and-lagooning/, accessed 5 April, 2021.

[7]https://www.build-green.fr/phytoepuration-creer-un-filtre-plante/?doing_wp_cron=161756 7011.8170158863067626953125, accessed 6 April, 2021.

[8] Ibidem

[9]https://www.researchgate.net/publication/326352770_Manual_de_sistemas_de_Wetlands_construidas_para_o_tratamento_de_esgotos_sanitario_implantacao_operacao_e_manutencao, accessed 6 April, 2021.

[10] Ibidem

[11] Ibidem

[12]https://www.build-green.fr/phytoepuration-creer-un-filtre-plante/?doing_wp_cron=1617567011.8170158863067626953125 , accessed 8 April, 2021.

[13]https://www.researchgate.net/publication/326352770_Manual_de_sistemas_de_Wetlands_construidas_para_o_tratamento_de_esgotos_sanitario_implantacao_operacao_e_manutencao, accessed 8 April, 2021.

[14] https://wiki.lowtechlab.org/wiki/Phyto%C3%A9puration_eaux_us%C3%A9es, accessed 8 April, 2021.

[15] Ibidem

[16]https://www.sciencedirect.com/topics/earth-and-planetary-sciences/water-purification-plant, accessed 9 April, 2021.

[17]https://www.build-green.fr/phytoepuration-creer-un-filtre-plante/?doing_wp_cron=1617567011.8170158863067626953125, accessed 9 April, 2021.

[18] https://www.sciencedirect.com/topics/earth-and-planetary-sciences/water-purification-plant, , accessed 11 April, 2021.

[19https://wiki.lowtechlab.org/wiki/Phyto%C3%A9puration_eaux_us%C3%A9es, accessed 11 April, 2021.

[20] Ibidem

[21] https://www.researchgate.net/publication/326352770_Manual_de_sistemas_de_Wetlands_construidas_para_o_tratamento_de_esgotos_sanitario_implantacao_operacao_e_manutencao, accessed 11 April, 2021.

The post Phytodepuration with Degre.47 first appeared on Critical Concrete.

Did you miss our previous article…

https://www.akbarconcreteworks.com/?p=202